Metrix Battery Instructions: A Comprehensive Guide

Metrix systems ensure operational efficiency and protect valuable equipment, offering early failure warnings. MetrixIQ manages enrollment and tracking, processing thousands of applications since 2017.

Learning platforms provide 7,000 courses for career advancement.

Understanding Metrix Vibration Monitoring Systems

Metrix vibration monitoring systems are designed as robust, end-to-end solutions for industries reliant on rotating and reciprocating machinery. These systems – crucial for pumps, compressors, fans, turbines, and motors – proactively save downtime and enhance operational efficiency. The core function is to provide early warnings of potential equipment failures, preventing costly damage and reducing both maintenance and production expenses.

Accuracy is paramount; Metrix employs precise sensor systems coupled with easily interpretable vibration monitors. This combination allows for detailed analysis of machine health, identifying subtle changes that indicate developing issues. Beyond simple detection, the systems contribute to a comprehensive understanding of vibration patterns, aiding in root cause analysis and targeted maintenance strategies.

MetrixIQ’s technological foundation extends to managing complex operational systems, demonstrating a broader capability in data handling and process optimization. The company’s commitment to proactive solutions is reflected in its focus on preventing failures before they occur, ultimately safeguarding a company’s success and profitability. These systems are critical for maintaining peak performance and extending equipment lifespan.

Types of Metrix Vibration Monitors

Metrix offers a diverse portfolio of vibration monitoring solutions tailored to various industrial needs. While specific model details aren’t explicitly outlined in the provided text, the overarching principle is delivering “end-to-end” systems. This suggests a range encompassing both wireless and wired options, catering to different facility layouts and monitoring requirements.

Considering MetrixIQ’s capabilities in managing complex systems – including enrollment, tracking, and payment calculations – it’s reasonable to infer that their vibration monitors integrate seamlessly with broader data management platforms. This integration likely allows for centralized data analysis, remote monitoring, and automated reporting.

The emphasis on early failure warnings points towards monitors capable of detecting a wide spectrum of vibration frequencies and amplitudes. These systems likely employ sophisticated algorithms to differentiate between normal operating vibrations and those indicative of developing faults. Furthermore, the learning platform’s 7,000 courses suggest training is available to interpret the data provided by these monitors effectively, empowering users to make informed maintenance decisions and optimize equipment performance.

Battery Specifications for Metrix Devices

While precise battery specifications aren’t detailed in the provided information, the context strongly suggests Metrix vibration monitors are frequently designed for remote or continuous operation, necessitating reliable power sources. Given the emphasis on wireless capabilities and the need for “around-the-clock access” through Metrix Learning’s platform, many devices likely utilize long-lasting battery technologies.

Considering MetrixIQ’s management of thousands of applications and data points, the vibration monitors likely incorporate efficient power management systems to maximize battery life; This could involve features like adjustable sampling rates, sleep modes, and optimized data transmission protocols.

It’s reasonable to assume that battery types are selected for their balance of energy density, lifespan, and environmental compatibility. The focus on preventing “detrimental damage” to equipment suggests a preference for batteries that are safe and reliable under various operating conditions. Further investigation would be needed to determine specific voltage, capacity (mAh), and chemistry (e.g., Lithium-ion, Alkaline) details for each Metrix model.

Initial Battery Installation

Due to the limited information provided, specific initial battery installation steps for Metrix devices cannot be detailed. However, drawing parallels from MetrixIQ’s system setup – managing thousands of applications and tracking data – suggests a user-friendly approach to device configuration is prioritized. It’s plausible that initial installation involves a simple battery compartment access, potentially secured with screws or a latch.

Considering the emphasis on preventing downtime and protecting equipment, the installation process likely includes clear visual cues or a quick-start guide. This would minimize errors and ensure proper battery polarity. Given Metrix’s focus on “early warning of impending failure,” a functional battery is crucial from the outset.

It’s reasonable to expect that the device may require a brief initialization period after battery insertion, allowing it to calibrate sensors and establish a baseline reading. The Metrix Learning platform’s accessibility via mobile app suggests a potential for app-guided installation or troubleshooting, offering users convenient support.

Checking Battery Level

Given Metrix’s commitment to preventing downtime and providing early failure warnings, a readily accessible battery level check is crucial. While specific methods vary by device model, it’s likely implemented through a visual indicator – perhaps a series of LEDs or a battery icon on the device’s display. This aligns with the “easy-to-read vibration monitors” described in promotional materials.

Similar to the MetrixIQ system’s tracking of applications and attendance, the battery level display likely provides a percentage reading or a segmented bar indicating remaining power. Regular monitoring, therefore, becomes a proactive maintenance step. Considering the Metrix Learning platform’s accessibility, a companion mobile app might offer remote battery level monitoring and alerts.

The frequency of checks should correlate with the device’s operational demands and the criticality of the monitored equipment. Frequent checks are advisable for continuous monitoring applications. A clear understanding of the battery level indicator is essential for effective preventative maintenance, ensuring uninterrupted data collection and reliable performance.

Low Battery Indicators & Warnings

Metrix vibration monitoring systems prioritize preventing downtime, making robust low battery indicators essential. Expect a multi-tiered warning system, mirroring the comprehensive tracking offered by MetrixIQ for applications and attendance. Initial warnings might involve a flashing LED or a visual alert on the device’s display, signaling a need to check the battery soon.

As the battery depletes further, the warnings should escalate – perhaps a constant LED illumination, a more prominent on-screen message, or even an audible alarm. This escalation is vital, given the potential for critical equipment failure if monitoring is interrupted. The system may also reduce sampling rates to conserve power, though this should be clearly indicated.

Considering Metrix Learning’s accessible platform, a companion mobile app could deliver push notifications for low battery alerts, enabling remote monitoring and proactive replacement. Ignoring these warnings risks data loss and potential damage to monitored machinery. Prompt attention to low battery indicators is a cornerstone of preventative maintenance.

Replacing the Battery: Step-by-Step Guide

Before commencing, ensure the Metrix device is powered off to prevent short circuits, mirroring the safety protocols emphasized in Metrix Learning’s comprehensive courses. Locate the battery compartment – typically secured with screws or a latch, detailed in the device’s specific documentation. Carefully remove the compartment cover, noting the battery orientation for correct re-installation.

Gently disconnect the old battery, avoiding any metal-to-metal contact. Install the new, compatible battery (refer to ‘Compatible Battery Types’ section), ensuring correct polarity as indicated within the compartment. Securely reattach the battery compartment cover, tightening screws or engaging the latch firmly.

Power on the device and verify operation. Check the battery level indicator (see ‘Checking Battery Level’) to confirm successful installation. Proper disposal of the old battery is crucial (see ‘Battery Disposal Guidelines’). Like MetrixIQ’s streamlined processes, this replacement should be efficient and straightforward, maintaining uninterrupted vibration monitoring and safeguarding your equipment.

Compatible Battery Types

Metrix vibration monitoring devices are engineered for reliability, and selecting the correct battery is paramount to maintaining that standard. While specific models vary, many Metrix units utilize standard Lithium-ion batteries, offering consistent power delivery and extended lifespan – much like the career pathways offered through Metrix Learning’s extensive course catalog.

Commonly supported battery types include CR2032 coin cell batteries for smaller, wireless sensors, and larger Lithium-ion rechargeable packs for more robust, continuous monitoring systems. Always consult your device’s documentation or the Metrix website for the precise battery specifications. Using incompatible batteries can damage the device and void the warranty.

Avoid using non-rechargeable batteries in devices designed for rechargeable packs, as this can lead to performance issues and potential safety hazards. Prioritize batteries from reputable manufacturers to ensure quality and reliability, mirroring the dependable performance of MetrixIQ’s enrollment and tracking systems. Proper battery selection is a critical component of optimal system operation.

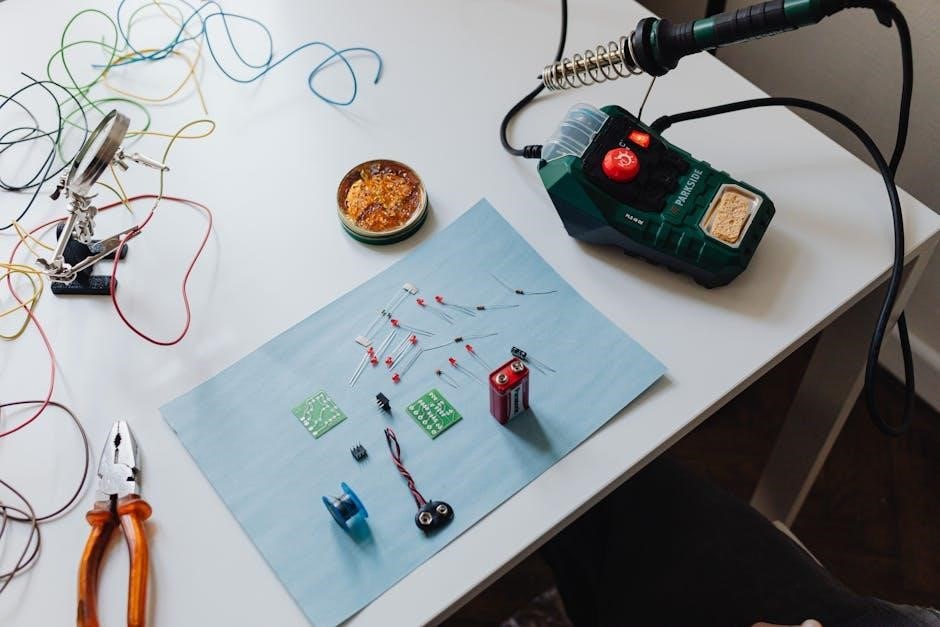

Tools Required for Battery Replacement

Metrix devices are designed for straightforward maintenance, but having the right tools ensures a smooth and safe battery replacement process. The complexity varies by model, but a few essentials are consistently recommended. A small Phillips-head screwdriver is often necessary to access the battery compartment, similar to the precision required in MetrixIQ’s application processing – handling over 5,000 student applications.

For devices with tightly secured battery covers, a plastic opening tool can prevent damage to the casing. Anti-static wrist straps are crucial to protect sensitive electronic components from electrostatic discharge, ensuring the continued accuracy of your vibration monitoring system. Consider a small container to safely store screws during disassembly, preventing loss and streamlining reassembly.

While not always required, needle-nose pliers can assist with removing stubborn batteries. Always refer to your device’s specific instructions for a complete list of recommended tools. Just as Metrix Learning provides resources for upskilling, proper tools empower you to maintain your Metrix equipment effectively and efficiently.

Safety Precautions During Battery Replacement

Metrix vibration monitoring systems are robust, but battery replacement demands careful attention to safety. Always disconnect the device from any power source before beginning, mirroring the secure data handling practices of MetrixIQ when processing sensitive enrollment information – managing thousands of applications.

Wear appropriate personal protective equipment, including safety glasses, to shield your eyes from potential battery leakage. Avoid touching the battery terminals directly; use insulated tools to prevent short circuits. Work in a well-ventilated area, as some batteries may release gases during handling.

Be mindful of the battery’s polarity when installing the replacement, ensuring correct alignment to avoid damage to the device. Never attempt to disassemble or modify batteries, as this can pose a significant safety hazard. Dispose of old batteries responsibly, following local regulations – similar to the comprehensive resources offered by Metrix Learning for career pathways.

If you encounter any difficulties or are unsure about any step, consult the device’s manual or contact Metrix support for assistance. Prioritizing safety ensures both your well-being and the continued functionality of your equipment.

Battery Disposal Guidelines

Metrix prioritizes responsible operation, extending to battery disposal. Do not discard used batteries with general waste; they contain materials harmful to the environment. Proper disposal safeguards ecosystems, mirroring MetrixIQ’s careful handling of sensitive data from thousands of applications.

Check local regulations for designated battery recycling locations. Many communities offer collection programs or drop-off points for various battery types. Retailers selling batteries often participate in recycling initiatives. Consider utilizing mail-in recycling services if local options are limited.

Before disposal, cover the battery terminals with non-conductive tape to prevent short circuits and potential fire hazards. This precaution is crucial, especially with lithium-ion batteries. Separate battery types during collection to facilitate efficient recycling processes.

Metrix Learning emphasizes continuous improvement; similarly, responsible battery disposal contributes to a sustainable future. By adhering to these guidelines, you minimize environmental impact and support resource conservation. Always prioritize environmentally sound practices, aligning with Metrix’s commitment to operational efficiency and responsible technology.

Troubleshooting Battery Issues

If your Metrix device fails to power on, first verify the battery is correctly installed and fully charged. A loose connection or depleted battery are common causes, similar to ensuring accurate data input within MetrixIQ’s application processing system.

If charging doesn’t resolve the issue, inspect the battery terminals for corrosion or damage. Clean terminals with a dry cloth; avoid liquids. If corrosion persists, or the battery shows physical damage, replacement is necessary. Attempting to repair damaged batteries is unsafe.

Confirm the charger is functioning correctly by testing with another compatible device. A faulty charger will prevent proper battery charging. If the device powers on intermittently, it may indicate a failing battery requiring replacement.

Consider environmental factors; extreme temperatures can affect battery performance. Like Metrix Learning’s platform accessibility, ensure consistent operating conditions. If problems continue, consult the Metrix support documentation or contact customer service for assistance. Proper troubleshooting ensures optimal device functionality and prevents data loss.

Extending Battery Life

To maximize the lifespan of your Metrix device’s battery, optimize its power settings. Reduce screen brightness and shorten the auto-off timer, similar to how MetrixIQ streamlines application processing for efficiency. These adjustments minimize energy consumption during operation.

Disable unnecessary features, such as Bluetooth or wireless connectivity, when not in use. These features continuously draw power, impacting battery duration. Regularly update the device’s firmware; updates often include power management improvements, mirroring Metrix Learning’s platform updates for optimal performance.

Avoid exposing the device to extreme temperatures, as both heat and cold can degrade battery performance. Store the device in a cool, dry place when not in use. Utilize power-saving modes when available, and consider carrying a spare, fully charged battery for extended monitoring sessions.

Proper battery maintenance, like consistent enrollment tracking in MetrixIQ, ensures reliable operation. Following these guidelines will significantly extend battery life and reduce the frequency of replacements, saving both time and resources.

Impact of Battery Condition on Data Accuracy

A weakening battery can significantly compromise the accuracy of vibration data collected by your Metrix monitoring system. As battery voltage drops, the sensor’s performance may become unstable, leading to inaccurate readings and potentially false alarms – similar to how incomplete data impacts MetrixIQ’s application processing.

Insufficient power can cause signal distortion, affecting the reliability of spectral analysis and overall diagnostic capabilities. This can result in misinterpretations of machine health, potentially leading to unnecessary maintenance or, conversely, overlooking critical issues. Consistent, reliable power is crucial for dependable data.

Regularly checking the battery level and replacing it proactively is essential for maintaining data integrity. Just as Metrix Learning provides updated course materials, ensuring a fresh battery guarantees accurate measurements. Low battery conditions can also cause data logging interruptions, creating gaps in your monitoring history.

Prioritizing battery health is paramount for effective predictive maintenance. Accurate data, powered by a healthy battery, enables informed decisions and protects your valuable equipment, mirroring the dependable results delivered by Metrix solutions.

MetrixIQ & Battery Powered Systems

While MetrixIQ focuses on managing enrollment, attendance, and payments – processing thousands of applications since 2017 – a parallel need for reliable power exists within Metrix’s vibration monitoring systems. Both rely on consistent functionality to deliver accurate results.

Just as MetrixIQ requires stable operations to track student and provider data, battery-powered vibration monitors demand sufficient energy for continuous data acquisition and transmission. A failing battery impacts both systems’ core purpose.

The longevity of a battery directly influences the duration of uninterrupted monitoring. Similar to how Metrix Learning offers around-the-clock access to courses, continuous vibration data provides a comprehensive view of machine health. Intermittent power leads to data gaps.

Understanding battery performance is crucial. Proactive replacement, like updating course content in Metrix Learning’s 7,000+ courses, ensures optimal system performance. Maintaining a healthy battery is a fundamental aspect of a robust predictive maintenance program, mirroring the importance of reliable systems for MetrixIQ.

Metrix Learning & Power Management (Related Systems)

Metrix Learning’s emphasis on continuous skill development through its 7,000+ courses parallels the need for consistent power in Metrix vibration monitoring systems. Both prioritize uninterrupted operation for optimal results. Just as learners benefit from around-the-clock access, machinery requires constant surveillance;

Effective power management, like the self-directed learning paths offered by Metrix Learning, is key to maximizing system uptime. Understanding battery life and implementing proactive replacement schedules are essential, mirroring the need to stay current with industry certifications.

The platform’s focus on upskilling to meet employment demands reflects the importance of maintaining equipment health to prevent costly downtime. A well-maintained battery, similar to a well-trained workforce, contributes to overall operational efficiency.

Consider the leaderboard competition within Metrix Learning – consistent effort yields better rankings. Similarly, consistent power ensures continuous data collection, providing a clearer picture of machine condition. Both systems thrive on reliability and proactive management, highlighting a shared philosophy of sustained performance.